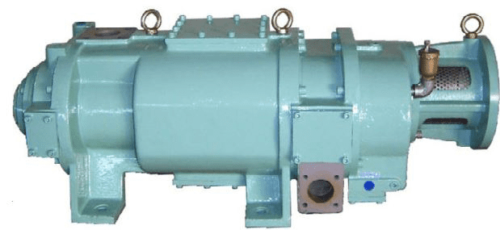

China Hot Selling 1.1Kw 20m3/h Air Cooled Dry Screw Vacuum Pump for Lab Vacuum Distillation

Introduction

The CHINAMFG dry compound screw vacuum pump is the latest innovation in vacuum pump technology. It uses the fifth-generation of compound variable pitch screw technology, which allows it to save up to 30% in energy and produces low exhaust temperatures. It is characterized by its high efficiency, energy-saving properties, environmental friendliness, lightweight design, easy operation, and reliable performance, making it the future of vacuum pumps.

The air-cooled design is 100% oil-free and features a self-designed multistage flat seal that can withstand strong resistance to water vapor. The screw rotors use the latest in variable pitch screw technology and have no contact with each other. The pump uses a mechanical flat seal for easy maintenance and has a maximum vacuum reach of 1Pa.

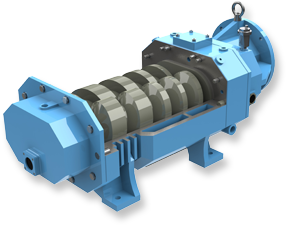

Working Principle

The dry compound screw vacuum pump consists of two parallel screw rotors and a pump body that form multiple sealed spaces. The rotors and pump body all have minuscule clearance, which means no touch and no friction. With reverse gear driving, gas continuously transfers from the inlet hole to the outlet hole. Due to the rotors and pump body not having friction, there is no need for lubricating oil, and the gas remains clean. The gas continuously transfers, with short passageways, high efficiency, and easy to clean. The outlet hole position is lower than the screw rotors and has strong drainage ability, better exhaust, and drainage, with no intermediate bulkhead.

Product Parameters

| Model | DPS571 | DPS050 | DPS080 |

| Pumping speed(m3/h) | 20 | 50 | 80 |

| Max Vacuum(Pa/Torr) | <3/0.02 | ||

| Motor Power(Kw/Hp) | 1.1/1.5 | 1.5/2.0 | 2.2/3.0 |

| Rotating Speed(RPM) | 2980 | ||

| Working Voltage(V/HZ/Phase) | 220-480 / 50/60 / 3 | ||

| Structure | Horizontal Type | ||

| Inlet Hole | KF25 | KF40 | KF40 |

| Outlet Hole | KF25 | KF25 | KF25 |

| Cooling Method | Air Cooled | ||

| Sealing Method | Mechanical Flat Seal | ||

| Gear/Bearing Lubrication | 100# Synthetic Gear Oil | ||

| Noise(dB) | 65 | 70 | 72 |

| Weight(Kg) | 47 | 61 | 69 |

| Dimension(LxWxH, MM) | 673x303x275 | 769x331x292 | 844x331x292 |

| Remark: 1m3/h=0.2778L/S, 1m3/h=0.5883CFM. 1Pa=0.01mbar, 1Pa=0.001Kpa, 1Pa=0.0075Torr, 1Pa=0.000145PSI, 1Pa=0.00001Bar. |

|||

CHINAMFG Other Industrial Products

Our company mainly supplies various industrial products, such as agricultural gearboxes, power output shafts, sprockets, hydraulic couplings, worm gear reducers, racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. Customers are welcome to customize with drawings and samples to fit their specific needs. We pride ourselves on providing high-quality products at preferential prices, coupled with thoughtful services.

Frequently Asked Questions

Q1: What do I need to provide when making an inquiry?

A1: Please provide your working vacuum degree (Pa, mbar, or Torr), flowrate (L/S or M3/H), and intended usage.

Q2: Do you have a minimum order quantity?

A2: We do not have a minimum order quantity. If you have a larger quantity, we will offer a discounted price.

Q3: How long is the delivery time?

A3: It takes approximately 4-5 weeks to produce, followed by an additional 5-7 days to arrange domestic delivery and port clearance.

Q4: What is your payment term?

A4: We require a 50% prepayment, with the balance paid before delivery via TT.

Q5: What is the warranty period?

A5: The product has a one-year warranty, starting from one month after the product arrives at the client’s site. If the pump fails, the client can either return it to the factory for repair or receive remote technical support.

Performance Characteristics of Screw Vacuum Pump

Screw vacuum pump is a kind of positive displacement vacuum pump, which has the characteristics of high vacuum, large pumping speed, compact structure, low noise, low vibration and long service life. It can pump various gases, especially for the pumping of large molecular gases and dust-containing gases. It has the advantages of high efficiency, energy saving and environmental protection, and is widely used in various industries.

Types and Characteristics of Screw Vacuum Pump

According to the different stages of vacuum, Screw vacuum pump can be divided into single-stage and multi-stage types. According to the different structures, it can be divided into dry screw vacuum pump and wet screw vacuum pump. Dry screw vacuum pump does not need lubricating oil, which can avoid oil pollution and oil vapor. Wet screw vacuum pump can pump flammable and explosive gases and some corrosive gases. In addition, screw vacuum pump can be made of different materials such as cast iron, stainless steel, aluminum alloy and composite materials, which have different advantages in different application scenarios.

Application of Screw Vacuum Pump

Screw vacuum pump has a wide range of applications, especially in the pharmaceutical, electronics, food and beverage, environmental and aerospace industries. In the pharmaceutical industry, screw vacuum pump is mainly used for the production of antibiotics, vaccines, blood products and other biological products. In the electronics industry, screw vacuum pump is mainly used for the production of semiconductors, liquid crystal displays and solar cells. In the food and beverage industry, screw vacuum pump is mainly used for the production of milk, juice, beer, wine and other beverages. In the environmental industry, screw vacuum pump is mainly used for the treatment of wastewater, landfill gas recovery and incineration. In the aerospace industry, screw vacuum pump is mainly used for the simulation of vacuum and microgravity environments.

Future Development Trends and Opportunities of Screw Vacuum Pump

With the development of science and technology, Screw vacuum pump is facing new challenges and opportunities. In the future, Screw vacuum pump will develop in the direction of high efficiency, low energy consumption, intelligence and integration. In particular, dry screw vacuum pump will become the mainstream product in the market, and the application fields will be more extensive. In addition, with the increasing demand for environmental protection, Screw vacuum pump will develop rapidly in the field of green vacuum technology.

How to Choose a Suitable Screw Vacuum Pump

When choosing a suitable Screw vacuum pump, several aspects should be considered: understand application requirements, performance specifications, energy efficiency, oil-free operation, safety features and cost considerations. Firstly, it is necessary to understand the application requirements of the vacuum system, such as vacuum degree, pumping speed, gas composition, etc. Secondly, it is necessary to select the appropriate performance specifications of Screw vacuum pump, such as ultimate vacuum, pumping speed, compression ratio, etc. Thirdly, it is necessary to consider the energy efficiency of Screw vacuum pump, such as power consumption, heat dissipation, etc. Fourthly, it is necessary to choose oil-free Screw vacuum pump if the pumped gas is sensitive to oil pollution. Fifthly, it is necessary to consider the safety features of Screw vacuum pump, such as overload protection, overheat protection, etc. Finally, it is necessary to consider the cost and economic benefits of Screw vacuum pump.

Summary

In summary, Screw vacuum pump is a kind of positive displacement vacuum pump with high efficiency, energy saving and environmental protection. It has a wide range of applications in various industries, and has a bright future in the development of green vacuum technology. When choosing a suitable Screw vacuum pump, various factors should be considered comprehensively to achieve the best performance and economic benefits.

Author: Dream

All the content of the page is from the Internet, the content is only as a reference for product selection, our products are replacement parts and not original spare parts; we are not the holder of the original trademarks of the content, our products are only suitable for after-sales replacement parts and not original spare parts, our replacement parts can be perfectly adapted to the original spare parts; if you need to buy original spare parts, please contact the original factory to buy. If you want to buy original spare parts, please contact the original supplier for purchase.