Product Description

Long Life Span Low Noise Suction Pump, Diaphragm Pump, Air Vacuum Pump

♦ 16000M2 modern factory with its own physical property rights, ESD anti-static control dust free workshop,

100+ sets of professional imported equipment

♦ 4 major professional and precision laboratories that meet the CNAS national laboratory accreditation standards

♦ More than 50 patents in the micro water pump industry, strong research and development strength, and master advanced industry technology

♦ Complete certification, passed CE, ROHS, REACH, WRAS, Food Grade and other certification

Remarks:

– We are high-end Micro DC pumps manufacturer. Can provide customized services

– If you are interested in our products, pls feel free to contact us

Our Micro Diaphragm Pumps are available with a choice of 4 different drive motors.

A- Premium duty brush DC motor

lifetime 3,000hours,longer endurance lifetime than other normal DC membrane pump

B- Economical brush DC motor

lifetime:1,500hours

C- Coreless Brushless DC Motor

A brushless electronically commutated dc motor (electronics integrated in motor), the motor runs vibration and spark free, almost silently, is very dynamic and extremely durable, ideal life-time 15000 hours

D- Coreless Brushless DC motor with outer controller

With all advantages of coreless brushless DC motor, ideal life-time 15000 hours, and outer controller can realize more control functions of PWM or 0 -5V speed adjustment, brake, ~ instant starting work

H- Brushless DC Motor

Long lifetime 10000hour

Product Specification

| Model | TM30A-A | TM30A-B | TM30A-C | TM30A-D |

| Motor type |

A–high performance Brush motor |

B–Brush motor | C–Brushless motor | D–Brushless motor |

| Pump Assembly Rated Life | 3000hour | 1000hour | 15000hour | 15000hour |

| Gas flow | 6L/min | 4.5L/min | 4.5L/min | 4L/min |

| Rated Voltage | 12V | 6/12/24v | 6/12/24v | 6/12/24v |

| No-load Current | 0.24A | 0.4/0.24/0.15A | ||

| Media | Most gas | |||

| Max Pressure | 120kpa | |||

| Max Vacuum | -70kpa | |||

| Ambient Temperature | 41 to 158 F(5 to 70C) | |||

| Pump size | 75.5*30.4*54.6mm | 75*31.2*57.5mm | 79*31.2*57.5mm | 79*31.2*57.5mm |

| Weight | 200g | 150g | 250g | 250g |

| Inlet&Outlet | OD 4.8mm/ID 2.6mm,hose suggestion:ID 4.0mm | |||

| Materials |

pump head Nylon, membrane EPDM , valve EPDM |

pump head Nylon, membrane EPDM / PTFE, valve EPDM / FPM |

pump head Nylon, membrane EPDM / PTFE, valve EPDM / FPM |

pump head Nylon, membrane EPDM / PTFE, valve EPDM / FPM |

| Wetted material options |

1.Optional membrane materials: 2.Optional valve materials: |

|||

Get more Technical data, Please Send message

CHINAMFG Diaphragm series gas pumps are the perfect combination of form and function. The use of a special diaphragm allows the pump to transfer both air and liquid efficiently. The compact lightweight unit offers optimum sizing for analytical equipment.

ADVANTAGES

♦ High pneumatic performance

♦ Compact size/high power density

♦ Uncontaminated flow – no contamination of the media due to oil-free operation

♦ Maintenance-free

♦ Long product life

♦ Low sound level

♦ Low power consumption

♦ Can operate in any orientation

♦ Suction

The versatility of CHINAMFG pumps allows a wide field of applications to be covered. Over many years our pumps have proved themselves in the following areas:

1.Industrial pressure and vacuum applications

2.Portable Analytical Instruments

3.Medical Equipment

4.Air Quality Sampling Monitors

5.Respiration Monitors

Performance Curve

More About Products

TOPS INDUSTRY AND TECHNOLOGY CO., LIMITED started in 2005, is the world’s leading supplier of micro

pump solutions, and won the “National High-tech Enterprise”. The company is mainly engaged in the research and development and manufacture of miniature brushless DC

pumps and miniature diaphragm pumps. 80% of the products are exported to high-end markets in Europe and

America, and are mainly used in water heaters, small household appliances, water heating mattresses, medical equipment, smart toilets, automobile circulation systems, etc. The company has always been known for its high quality and high batch consistency, and has established solid and good cooperative relations with many world-renowned brands, such as: Tesla, Whirlpool, Flextronics, Kohler, GE, Roca, KTM, Geberit, etc.

Get more Technical data, Please Send message

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Pump Head Nylon, Membrane EPDM / PTFE, Valve EPDM |

|---|---|

| Power: | Electric |

| Valve Body Type: | Diaphragm |

| Function: | Intelligent Type, Air Quality Sampling Monitors Respiration Monitors |

| Motor: | DC Brushless Motor |

| Lifetime: | 15, 000hours |

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used in the Aerospace Sector?

Vacuum pumps indeed have various applications in the aerospace sector. Here’s a detailed explanation:

Vacuum pumps play a crucial role in several areas of the aerospace industry, supporting various processes and systems. Some of the key applications of vacuum pumps in the aerospace sector include:

1. Space Simulation Chambers: Vacuum pumps are used in space simulation chambers to replicate the low-pressure conditions experienced in outer space. These chambers are utilized for testing and validating the performance and functionality of aerospace components and systems under simulated space conditions. Vacuum pumps create and maintain the necessary vacuum environment within these chambers, allowing engineers and scientists to evaluate the behavior and response of aerospace equipment in space-like conditions.

2. Propellant Management: In space propulsion systems, vacuum pumps are employed for propellant management. They help in the transfer, circulation, and pressurization of propellants, such as liquid rocket fuels or cryogenic fluids, in both launch vehicles and spacecraft. Vacuum pumps assist in creating the required pressure differentials for propellant flow and control, ensuring efficient and reliable operation of propulsion systems.

3. Environmental Control Systems: Vacuum pumps are utilized in the environmental control systems of aircraft and spacecraft. These systems are responsible for maintaining the desired atmospheric conditions, including temperature, humidity, and cabin pressure, to ensure the comfort, safety, and well-being of crew members and passengers. Vacuum pumps are used to regulate and control the cabin pressure, facilitating the circulation of fresh air and maintaining the desired air quality within the aircraft or spacecraft.

4. Satellite Technology: Vacuum pumps find numerous applications in satellite technology. They are used in the fabrication and testing of satellite components, such as sensors, detectors, and electronic devices. Vacuum pumps help create the necessary vacuum conditions for thin film deposition, surface treatment, and testing processes, ensuring the performance and reliability of satellite equipment. Additionally, vacuum pumps are employed in satellite propulsion systems to manage propellants and provide thrust for orbital maneuvers.

5. Avionics and Instrumentation: Vacuum pumps are involved in the production and testing of avionics and instrumentation systems used in aerospace applications. They facilitate processes such as thin film deposition, vacuum encapsulation, and vacuum drying, ensuring the integrity and functionality of electronic components and circuitry. Vacuum pumps are also utilized in vacuum leak testing, where they help create a vacuum environment to detect and locate any leaks in aerospace systems and components.

6. High Altitude Testing: Vacuum pumps are used in high altitude testing facilities to simulate the low-pressure conditions encountered at high altitudes. These testing facilities are employed for evaluating the performance and functionality of aerospace equipment, such as engines, materials, and structures, under simulated high altitude conditions. Vacuum pumps create and control the required low-pressure environment, allowing engineers and researchers to assess the behavior and response of aerospace systems in high altitude scenarios.

7. Rocket Engine Testing: Vacuum pumps are crucial in rocket engine testing facilities. They are utilized to evacuate and maintain the vacuum conditions in engine test chambers or nozzles during rocket engine testing. By creating a vacuum environment, these pumps simulate the conditions experienced by rocket engines in the vacuum of space, enabling accurate testing and evaluation of engine performance, thrust levels, and efficiency.

It’s important to note that aerospace applications often require specialized vacuum pumps capable of meeting stringent requirements, such as high reliability, low outgassing, compatibility with propellants or cryogenic fluids, and resistance to extreme temperatures and pressures.

In summary, vacuum pumps are extensively used in the aerospace sector for a wide range of applications, including space simulation chambers, propellant management, environmental control systems, satellite technology, avionics and instrumentation, high altitude testing, and rocket engine testing. They contribute to the development, testing, and operation of aerospace equipment, ensuring optimal performance, reliability, and safety.

What Is the Role of Vacuum Pumps in Pharmaceutical Manufacturing?

Vacuum pumps play a crucial role in various aspects of pharmaceutical manufacturing. Here’s a detailed explanation:

Vacuum pumps are extensively used in pharmaceutical manufacturing processes to support a range of critical operations. Some of the key roles of vacuum pumps in pharmaceutical manufacturing include:

1. Drying and Evaporation: Vacuum pumps are employed in drying and evaporation processes within the pharmaceutical industry. They facilitate the removal of moisture or solvents from pharmaceutical products or intermediates. Vacuum drying chambers or evaporators utilize vacuum pumps to create low-pressure conditions, which lower the boiling points of liquids, allowing them to evaporate at lower temperatures. By applying vacuum, moisture or solvents can be efficiently removed from substances such as active pharmaceutical ingredients (APIs), granules, powders, or coatings, ensuring the desired product quality and stability.

2. Filtration and Filtrate Recovery: Vacuum pumps are used in filtration processes for the separation of solid-liquid mixtures. Vacuum filtration systems typically employ a filter medium, such as filter paper or membranes, to retain solids while allowing the liquid portion to pass through. By applying vacuum to the filtration apparatus, the liquid is drawn through the filter medium, leaving behind the solids. Vacuum pumps facilitate efficient filtration, speeding up the process and improving product quality. Additionally, vacuum pumps can aid in filtrate recovery by collecting and transferring the filtrate for further processing or reuse.

3. Distillation and Purification: Vacuum pumps are essential in distillation and purification processes within the pharmaceutical industry. Distillation involves the separation of liquid mixtures based on their different boiling points. By creating a vacuum environment, vacuum pumps lower the boiling points of the components, allowing them to vaporize and separate more easily. This enables efficient separation and purification of pharmaceutical compounds, including the removal of impurities or the isolation of specific components. Vacuum pumps are utilized in various distillation setups, such as rotary evaporators or thin film evaporators, to achieve precise control over the distillation conditions.

4. Freeze Drying (Lyophilization): Vacuum pumps are integral to the freeze drying process, also known as lyophilization. Lyophilization is a dehydration technique that involves the removal of water or solvents from pharmaceutical products while preserving their structure and integrity. Vacuum pumps create a low-pressure environment in freeze drying chambers, allowing the frozen product to undergo sublimation. During sublimation, the frozen water or solvent directly transitions from the solid phase to the vapor phase, bypassing the liquid phase. Vacuum pumps facilitate efficient and controlled sublimation, leading to the production of stable, shelf-stable pharmaceutical products with extended shelf life.

5. Tablet and Capsule Manufacturing: Vacuum pumps are utilized in tablet and capsule manufacturing processes. They are involved in the creation of vacuum within tablet presses or capsule filling machines. By applying vacuum, the air is removed from the die cavity or capsule cavity, allowing for the precise filling of powders or granules. Vacuum pumps contribute to the production of uniform and well-formed tablets or capsules by ensuring accurate dosing and minimizing air entrapment, which can affect the final product quality.

6. Sterilization and Decontamination: Vacuum pumps are employed in sterilization and decontamination processes within the pharmaceutical industry. Autoclaves and sterilizers utilize vacuum pumps to create a vacuum environment before introducing steam or chemical sterilants. By removing air or gases from the chamber, vacuum pumps assist in achieving effective sterilization or decontamination by enhancing the penetration and distribution of sterilants. Vacuum pumps also aid in the removal of sterilants and residues after the sterilization process is complete.

It’s important to note that different types of vacuum pumps, such as rotary vane pumps, dry screw pumps, or liquid ring pumps, may be utilized in pharmaceutical manufacturing depending on the specific requirements of the process and the compatibility with pharmaceutical products.

In summary, vacuum pumps play a vital role in various stages of pharmaceutical manufacturing, including drying and evaporation, filtration and filtrate recovery, distillation and purification, freeze drying (lyophilization), tablet and capsule manufacturing, as well as sterilization and decontamination. By enabling efficient and controlled processes, vacuum pumps contribute to the production of high-quality pharmaceutical products, ensuring the desired characteristics, stability, and safety.

Can Vacuum Pumps Be Used in Laboratories?

Yes, vacuum pumps are extensively used in laboratories for a wide range of applications. Here’s a detailed explanation:

Vacuum pumps are essential tools in laboratory settings as they enable scientists and researchers to create and control vacuum or low-pressure environments. These controlled conditions are crucial for various scientific processes and experiments. Here are some key reasons why vacuum pumps are used in laboratories:

1. Evaporation and Distillation: Vacuum pumps are frequently used in laboratory evaporation and distillation processes. By creating a vacuum, they lower the boiling point of liquids, allowing for gentler and more controlled evaporation. This is particularly useful for heat-sensitive substances or when precise control over the evaporation process is required.

2. Filtration: Vacuum filtration is a common technique in laboratories for separating solids from liquids or gases. Vacuum pumps create suction, which helps draw the liquid or gas through the filter, leaving the solid particles behind. This method is widely used in processes such as sample preparation, microbiology, and analytical chemistry.

3. Freeze Drying: Vacuum pumps play a crucial role in freeze drying or lyophilization processes. Freeze drying involves removing moisture from a substance while it is in a frozen state, preserving its structure and properties. Vacuum pumps facilitate the sublimation of frozen water directly into vapor, resulting in the removal of moisture under low-pressure conditions.

4. Vacuum Ovens and Chambers: Vacuum pumps are used in conjunction with vacuum ovens and chambers to create controlled low-pressure environments for various applications. Vacuum ovens are used for drying heat-sensitive materials, removing solvents, or conducting reactions under reduced pressure. Vacuum chambers are utilized for testing components under simulated space or high-altitude conditions, degassing materials, or studying vacuum-related phenomena.

5. Analytical Instruments: Many laboratory analytical instruments rely on vacuum pumps to function properly. For example, mass spectrometers, electron microscopes, surface analysis equipment, and other analytical instruments often require vacuum conditions to maintain sample integrity and achieve accurate results.

6. Chemistry and Material Science: Vacuum pumps are employed in numerous chemical and material science experiments. They are used for degassing samples, creating controlled atmospheres, conducting reactions under reduced pressure, or studying gas-phase reactions. Vacuum pumps are also used in thin film deposition techniques like physical vapor deposition (PVD) and chemical vapor deposition (CVD).

7. Vacuum Systems for Experiments: In scientific research, vacuum systems are often designed and constructed for specific experiments or applications. These systems can include multiple vacuum pumps, valves, and chambers to create specialized vacuum environments tailored to the requirements of the experiment.

Overall, vacuum pumps are versatile tools that find extensive use in laboratories across various scientific disciplines. They enable researchers to control and manipulate vacuum or low-pressure conditions, facilitating a wide range of processes, experiments, and analyses. The choice of vacuum pump depends on factors such as required vacuum level, flow rate, chemical compatibility, and specific application needs.

editor by Dream 2024-05-16

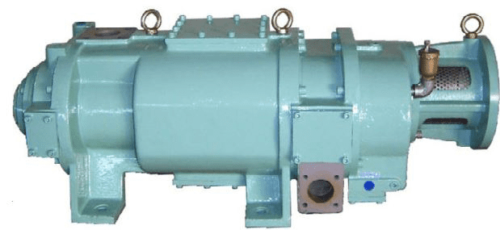

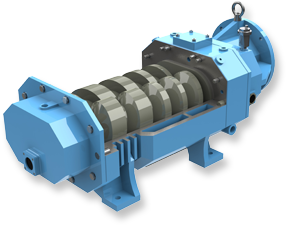

China best Air Cooled Screw Vacuum Pumps for Vacuum Evaporation vacuum pump engine

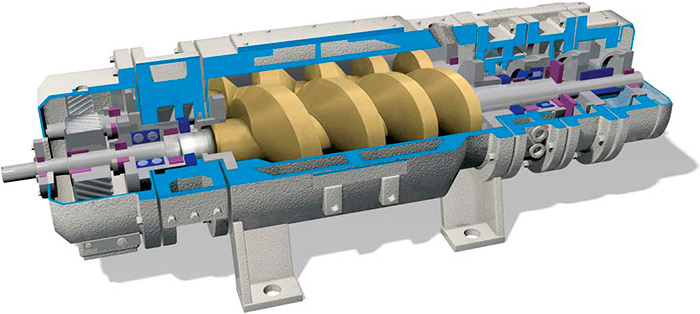

Product Description

Product Description

Dry screw vacuum pump, is the use of a pair of screw, made in the pump shell synchronous high-speed reverse rotation of the effects of the suction and exhaust and suction device, 2 screw fine dynamic balancing correction, and is supported by bearings, is installed in the pump shell, between screw and screw has a certain gap, so the pump work, no friction between each other, smooth running, low noise, Working chamber without lubricating oil, therefore, dry screw pump can remove a lot of steam and a small amount of dust gas occasions, higher limit vacuum, lower power consumption, energy saving, maintenance-free and other advantages.

Our Advantages

There is no medium in the working chamber, which can obtain a clean vacuum.

. No clearance between rotating parts, high speed operation, small overall volume.

There is no compression in the gas, suitable for extraction of coagulable gas.

Can remove a lot of steam and a small amount of dust gas occasions.

. High vacuum, the ultimate vacuum up to 1 Pa.

Screw material is high strength special material, material density, wear resistance, stable performance.

No friction rotating parts, low noise.

. Simple structure, convenient maintenance.

Wider range of use: corrosive environment can be used.

No oil consumption, no water.

Pump gas directly discharged from the pump body, no pollution of water, no environmental pressure, more convenient gas recovery.

It can be composed of oil-free unit with Roots pump and molecular pump.

Typical Use

——Oil and gas recovery. ——Biological medicine ——Food Processing —— Single crystal furnace

——Vacuum forming ——Vacuum flame refining ——Electronic photovoltaic. ——Semiconductor synthesis

Product Parameters

| Type | Basic parameters | ||||||||

| Pumping speed m3/h |

Presure limit(Pa) | Power (kW) | revolution (rpm) | Inlet caliber mm |

outlet caliber mm | Cooling water volume L/min |

noise dB(A) | Overall dimension (length*width*height) mm |

|

| LGV-180 | 180 | 5 | 4 | 2900 | 40 | 40 | 2 | < 78 | 1157x375x734 |

| LGV-250 | 250 | 5 | 5.5 | 2900 | 50 | 40 | 5.5 | <78 | 1462x417x820 |

| LGV-360 | 360 | 5 | 7.5 | 2900 | 50 | 40 | 4 | W78 | 1462x455x820 |

| LGV-540 | 540 | 5 | 11 | 2900 | 65 | 50 | 8 | W80 | 1578x543x860 |

| LGV-720 | 720 | 5 | 15 | 2900 | 80 | 65 | 10 | <80 | 1623x562x916 |

| LGV-1100 | 1100 | 5 | 22 | 2900 | 100 | 80 | 14 | w 80 | 1866x598x1050 |

| LG V-1800 | 1800 | 5 | 37 | 2900 | 150 | 100 | 20 | w 80 | 2092×951 x 1150 |

Characteristic Curve

Detailed Photos

General Manager Speech

Deeply cultivate the vacuum technology, and research,develop and manufacture the vacuum equipment to provide the best solution in the vacuum field and make the vacuum application easier.

Company Profile

ZheJiang Kaien Vacuum Technology Co., Ltd. is a high-tech enterprise integrating R & D, production and operation of vacuum equipment. The company has strong technical force, excellent equipment and considerate after-sales service. The product manufacturing process is managed in strict accordance with IS09001 quality system. It mainly produces and sells screw vacuum pump, roots pump, claw vacuum pump, runoff vacuum pump, scroll pump, water ring vacuum pump, vacuum unit and other vacuum systems.

The company’s products have been for a number of food, medicine, refrigeration, drying plants and a number of transformer related equipment manufacturers for vacuum equipment. The products are widely used in vacuum drying and dehydration, kerosene vapor phase drying, vacuum impregnation, vacuum metallurgy, vacuum coating, vacuum evaporation, vacuum concentration, oil and gas recovery, etc.

The company cooperates with colleges and universities to research and develop core technologies, and owns dozens of independent intellectual property patents. Adhering to the basic tenet of quality, reputation and service, the company takes leading-edge technology of vacuum pump as its own responsibility, and wholeheartedly serves customers of vacuum equipment application in various industries with rigorous working attitude and professional working style.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | Lifetime Paid Service |

|---|---|

| Warranty: | One Year |

| Oil or Not: | Oil Free |

| Structure: | Screw |

| Exhauster Method: | Entrapment Vacuum Pump |

| Vacuum Degree: | High Vacuum |

| Customization: |

Available

|

|

|---|

Can screw vacuum pumps be used in food processing and packaging industries?

Yes, screw vacuum pumps can be used in food processing and packaging industries. Here’s a detailed explanation of their suitability and applications in these industries:

1. Vacuum Packaging:

Screw vacuum pumps are commonly used in vacuum packaging applications within the food industry. Vacuum packaging helps extend the shelf life of food products by removing air from the packaging, reducing spoilage, and preserving freshness. Screw vacuum pumps create the necessary vacuum environment by efficiently evacuating air from the packaging containers or bags. Their oil-free operation ensures that there is no risk of oil contamination in the packaged food, making them ideal for maintaining food quality and safety standards.

2. Food Processing:

Screw vacuum pumps are also suitable for various food processing applications. They can be used in processes such as deaeration, freeze drying, and evaporation. In deaeration processes, screw vacuum pumps efficiently remove air and gases from food mixtures, improving the quality and texture of the final product. In freeze drying, screw vacuum pumps facilitate the removal of moisture from frozen food products, preserving their nutritional value and extending their shelf life. Similarly, in evaporation processes, screw vacuum pumps help create the necessary vacuum conditions for concentrating liquids and reducing their volume, such as in the production of fruit juices or dairy products.

3. Sanitary Design:

Screw vacuum pumps designed for food processing and packaging industries often incorporate sanitary features to meet strict hygiene standards. These pumps are constructed with materials that are resistant to corrosion and can withstand frequent cleaning and sterilization processes. They may also have smooth surfaces, rounded edges, and minimal crevices to prevent the accumulation of food particles or bacteria. Sanitary design ensures compliance with food safety regulations and facilitates easy cleaning, reducing the risk of contamination and ensuring the integrity of the food products.

4. Contamination Prevention:

The oil-free operation of screw vacuum pumps is particularly advantageous in food processing and packaging industries. Since oil-free pumps eliminate the risk of oil contamination, they are suitable for processes where maintaining the purity and quality of food products is critical. Oil contamination can affect the taste, odor, and overall quality of food items. By using oil-free screw vacuum pumps, manufacturers can ensure that their products remain uncontaminated and meet the required food safety standards.

5. Efficiency and Reliability:

Screw vacuum pumps are known for their efficiency and reliability. They offer consistent performance and can handle varying load demands effectively. This is beneficial in food processing and packaging industries, where the production volumes can vary, and reliable vacuum generation is crucial. The robust design and low maintenance requirements of screw vacuum pumps contribute to their overall reliability, minimizing downtime and ensuring continuous operation in food processing and packaging facilities.

6. Compliance with Regulations:

Screw vacuum pumps designed for food processing and packaging industries are often manufactured to comply with relevant regulations and standards. These pumps may adhere to guidelines such as the Food and Drug Administration (FDA) regulations or the European Hygienic Engineering and Design Group (EHEDG) standards. Compliance with these regulations ensures that the equipment meets the necessary hygiene and safety requirements for food processing and packaging applications.

In summary, screw vacuum pumps can be effectively used in food processing and packaging industries. Their applications include vacuum packaging, food processing processes like deaeration, freeze drying, and evaporation. With their sanitary design, contamination prevention capabilities, efficiency, reliability, and compliance with regulations, screw vacuum pumps offer reliable and safe vacuum solutions for the food industry.

What is the range of vacuum levels that screw vacuum pumps can achieve?

Screw vacuum pumps are capable of achieving a wide range of vacuum levels, depending on the specific design and operating characteristics of the pump. Here is a detailed explanation of the typical range of vacuum levels that screw vacuum pumps can achieve:

1. Low Vacuum:

Screw vacuum pumps can operate in the low vacuum range, typically defined as vacuum levels between atmospheric pressure (760 torr) and around 1 torr. In this range, screw vacuum pumps can efficiently handle applications that require moderate vacuum levels, such as packaging, drying processes, and general industrial applications.

2. Medium Vacuum:

Screw vacuum pumps are also suitable for medium vacuum applications, which typically range from about 1 torr down to approximately 10^-3 torr (or 0.001 torr). In this range, screw vacuum pumps offer reliable performance and can be used in various industries and processes, including chemical processing, vacuum distillation, freeze drying, and composite manufacturing.

3. High Vacuum:

While screw vacuum pumps are not typically used for achieving ultra-high vacuum levels, they can still operate in the high vacuum range. High vacuum is generally defined as vacuum levels below 10^-3 torr (or 0.001 torr) down to around 10^-6 torr (or 0.000001 torr). Screw vacuum pumps can be employed in high vacuum applications where slightly higher pressures are acceptable, such as in research laboratories, vacuum coating, and some semiconductor manufacturing processes.

It’s important to note that the achievable vacuum levels may vary depending on factors such as the specific design and size of the screw vacuum pump, the gas composition being pumped, system conductance, and the presence of any leaks or contaminants in the vacuum system. Additionally, the performance of a screw vacuum pump may also be influenced by the process conditions and the specific application requirements.

In summary, screw vacuum pumps can achieve vacuum levels ranging from low vacuum (around 1 torr) to medium vacuum (down to approximately 10^-3 torr) and can also operate in the high vacuum range (below 10^-3 torr). The appropriate range of vacuum level for a specific application should be determined based on the process requirements, industry standards, and the capabilities of the screw vacuum pump.

What are the typical applications of screw vacuum pumps in various industries?

Screw vacuum pumps find a wide range of applications across various industries due to their efficiency, reliability, and versatility. Here are some typical applications of screw vacuum pumps in different industries:

Chemical Processing:

- Vacuum distillation and drying processes

- Vacuum filtration and solvent recovery

- Crystallization and evaporation systems

- Chemical reactors and vacuum drying ovens

Pharmaceuticals:

- Vacuum drying and freeze-drying of pharmaceutical products

- Deaeration and degassing processes

- Vacuum packaging and sealing

- Purification and distillation of pharmaceutical compounds

Food and Beverage:

- Deaeration and removal of dissolved gases in food and beverage products

- Evaporation and concentration processes

- Freeze drying and vacuum packaging

- Vacuum cooling and drying of food products

Power Generation:

- Steam condenser and turbine exhaust applications

- Deaeration and vacuum systems in power plants

- Vacuum distillation in the production of power plant chemicals

- Transformer drying and impregnation

Electronics Manufacturing:

- Vacuum drying and degassing of electronic components

- Vacuum soldering and brazing processes

- Thin film deposition and vacuum coating

- Printed circuit board manufacturing

Wastewater Treatment:

- Vacuum filtration and sludge dewatering

- Vacuum degassing and deaeration of wastewater

- Evaporation and concentration of wastewater streams

Environmental Applications:

- Landfill gas recovery and treatment

- Vacuum drying and deodorization in waste management

- Vacuum systems for air pollution control

Other Industries:

- Oil and gas industry for vapor recovery and gas processing

- Automotive industry for vacuum metallurgy and component manufacturing

- Textile industry for vacuum drying and deaeration of fabrics

- Research and development laboratories for various scientific applications

These are just a few examples of the many applications of screw vacuum pumps in various industries. The versatility and reliability of screw vacuum pumps make them suitable for a wide range of vacuum-related processes, enabling enhanced productivity, improved product quality, and cost savings in diverse industrial settings.

editor by Dream 2024-05-14

China Hot selling Industrial Vacuum Pump High Pressure Air Blower Xgb Vortex Gas Air Pump CNC Machine Compressor Vacuum Pump for CNC Router Tableno Reviews Yet vacuum pump engine

Product Description

Product Description

Customized support OEM

Place of Origin China

Power Source Electric

Structure Vacuum Pump

Warranty 1 year

Brand Name lq

Model Number customized

Horsepower /

Outlet Size /

Power /

motor /

Product name air pump

Voltage 380V

Warranty 1year

Material aluminium alloy

Type air

Keywords pump

MOQ 1set

frequency 50/60 Hz

phase 3 phase

Certification ce

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Product Name: | Air Pump |

|---|---|

| Voltage: | 380V |

| Warranty: | 1year |

| Material: | Aluminium Alloy |

| Type: | Air |

| Keywords: | Pump |

| Customization: |

Available

|

|

|---|

Types of vacuum pumps

A vacuum pump is a device that draws gas molecules from a sealed volume and maintains a partial vacuum. Its job is to create a vacuum in a volume, usually one of several. There are several types of vacuum pumps, such as root pumps, diaphragm pumps, rotary piston pumps, and self-priming centrifugal pumps.

The diaphragm pump is a dry positive displacement vacuum pump

Diaphragm pumps are a versatile type of vacuum pump. They can be installed in a variety of scenarios including container emptying, positive suction, and simultaneous fluid mixing. Their performance depends on the stiffness and durability of the diaphragm, which in turn depends on the material.

They have good performance when running in dry mode. Diaphragm pumps work very similarly to the human heart, which is why they are often used to create artificial hearts. In addition, the diaphragm pump is self-priming and has high efficiency. They are also capable of handling the most viscous liquids and are used in almost all industries.

However, this type of pump has several disadvantages. One of them is that they are difficult to restart after a power outage. Another disadvantage is that they can generate a lot of heat. Fortunately, this heat is carried away by airflow. However, this heat builds up in the multistage pump. If this happens, the diaphragm or motor may be damaged. Diaphragm pumps operating in two or more stages should be fitted with solenoid valves to maintain vacuum stability.

Diaphragm pumps are a good choice for drying processes where hygiene is important. These pumps have check valves and rubber or Teflon diaphragms. Diaphragm pumps are also ideal for high viscosity applications where shear sensitivity is important.

Roots pumps are dry method centrifugal pumps

Roots pumps use a vane rotor pump with two counter-rotating vanes that move in opposite directions to move the gas. They are often the first choice for high-throughput process applications. Depending on the size and number of blades, they can withstand up to 10 Torr.

Centrifugal pumps have several advantages, including the ability to handle corrosive fluids and high temperatures. However, when choosing a pump, it is essential to choose a reputable manufacturer. These companies will be able to advise you on the best pump design for your needs and provide excellent after-sales support. Roots pumps can be used in a wide range of industrial applications including chemical, food, and biotechnology.

The Roots pump is a dry centrifugal pump whose geometry enables it to achieve high compression ratios. The screw rotors are synchronized by a set of timing gears that allow gas to pass in both directions and create a compressed state in the chamber. The pre-compressed gas is discharged through a pressure connection and cooled with water. Some pumps are also able to accept additional cooling gas, but this should be done with caution.

The size of the impeller plays an important role in determining the pump head. The impeller diameter determines how high the pump can lift the liquid. Impeller speed also affects the head. Since the head is proportional to the specific gravity of the liquid, the available suction pressure will be proportional to the density of the liquid. The density of water is about 1.2 kg/m3, and the suction pressure of the centrifugal pump is not enough to lift the water.

The rotary vane pump is a self-priming centrifugal pump

A rotary vane pump is a centrifugal pump with a circular pump head and a cycloid cam that supports the rotor. The rotor is close to the cam wall, and two side plates seal the rotor. Vanes in vane pumps are installed in these cavities, and the rotor rotates at high speed, pushing fluid in and out of the pump. The pump offers several advantages, including a reversible design and the ability to handle a wide variety of clean fluids.

Agknx Pumps manufactures a wide range of vane pumps that combine high performance, low cost, and easy maintenance. These pumps handle medium to high viscosity liquids up to 500 degrees Fahrenheit and 200,000 SSU.

The suction side of the rotary vane pump has a discharge port, and the valve prevents the backflow of the discharge air. When the maximum pressure is reached, the outlet valve closes to prevent the backflow of exhaust gas. The mechanical separation step separates the oil from the gas in the pump circuit and returns the remaining oil particles to the sump. The float valve then reintroduces these oil particles into the oil circuit of the pump. The gas produced is almost oil-free and can be blown out of a pipe or hose.

Rotary vane pumps are self-priming positive displacement pumps commonly used in hydraulic, aeration, and vacuum systems. Unlike gear pumps, rotary vane pumps can maintain high-pressure levels while using relatively low suction pressures. The pump is also very effective when pumping viscous or high-viscosity liquids.

Rotary piston pumps are dry method positive displacement pumps

Rotary piston pumps are dry positive displacement pumps designed to deliver high-viscosity fluids. They are capable of pumping a variety of liquids and can run dry without damaging the liquid. Rotary piston pumps are available in a variety of designs. Some are single shafts, some are two shafts and four bearings.

Positive displacement pumps operate slower than centrifugal pumps. This feature makes the positive displacement pump more sensitive to wear. Piston and plunger reciprocating pumps are particularly prone to wear. For more demanding applications, progressive cavity, diaphragm or lobe pumps may be a better choice.

Positive displacement pumps are typically used to pump high-viscosity fluids. This is because the pump relies on a mechanical seal between the rotating elements and the pump casing. As a result, when fluids have low viscosity, their performance is limited. Additionally, low viscosity fluids can cause valve slippage.

These pumps have a piston/plunger arrangement using stainless steel rotors. Piston/piston pumps have two cavities on the suction side. The fluid then flows from one chamber to the other through a helical motion. This results in very low shear and pulsation rates. The pump is usually installed in a cylindrical housing.

Rotary vane pump corrosion resistance

Rotary vane vacuum pumps are designed for use in a variety of industries. They feature plasma-treated corrosion-resistant parts and anti-suck-back valves to help reduce the number of corrosive vapors entering the pump. These pumps are commonly used in freeze dryers, vacuum ovens, and degassing processes. The high flow rates they provide in their working vacuum allow them to speed up processes and reduce the time it takes to run them. Plus, they have energy-efficient motors and silent volume. <br/While rotary vane vacuum pumps are relatively corrosion resistant, they should not be used for aggressive chemicals. For these chemicals, the most suitable pump is the chemical mixing pump, which combines two types of pumps to improve corrosion resistance. If the application requires a more powerful pump, a progressive cavity pump (eg VACUU*PURE 10C) is suitable.

Oil seals used in rotary vane pumps are important to pump performance. The oil seal prevents corrosion of the aluminum parts of the rotary vane pump and prolongs the service life. Most rotary vane vacuum pumps have a standard set of components, although each component may have different oil seals.

Rotary vane vacuum pumps are the most common type of positive displacement pump. They provide quiet operation and long service life. They are also reliable and inexpensive and can be used in a variety of applications.

Roots pumps are primarily used as a vacuum booster

Root vacuum pumps are mainly used as vacuum boosters in industrial applications. They need a thorough understanding of operating principles and proper maintenance to function properly. This course is an introduction to Roots vacuum pumps, covering topics such as pump principles, multi-stage pumps, temperature effects, gas cooling, and maintenance.

Roots pumps have many advantages, including compact and quiet operation. They do not generate particles and have a long service life. They also don’t require oil and have a small footprint. However, Roots pumps have several disadvantages, including relatively high maintenance costs and low pumping speeds near atmospheric pressure.

Root vacuum pumps are often used with rotary vane vacuum pumps. They work on the same principle, the air enters a conveying unit formed by two rolling pistons in the housing. The piston heads are separated from each other, and the air passes through the unit without being reduced until it is discharged. When the air in the next unit reaches a higher absolute pressure, it is expelled from the last unit.

Roots pumps can be classified as sheathed or sealed. Roots pumps with sealed motors are suitable for pumping toxic gases. They have less clearance between the stator and motor rotor and have a sealed tank.

editor by Dream 2024-05-10

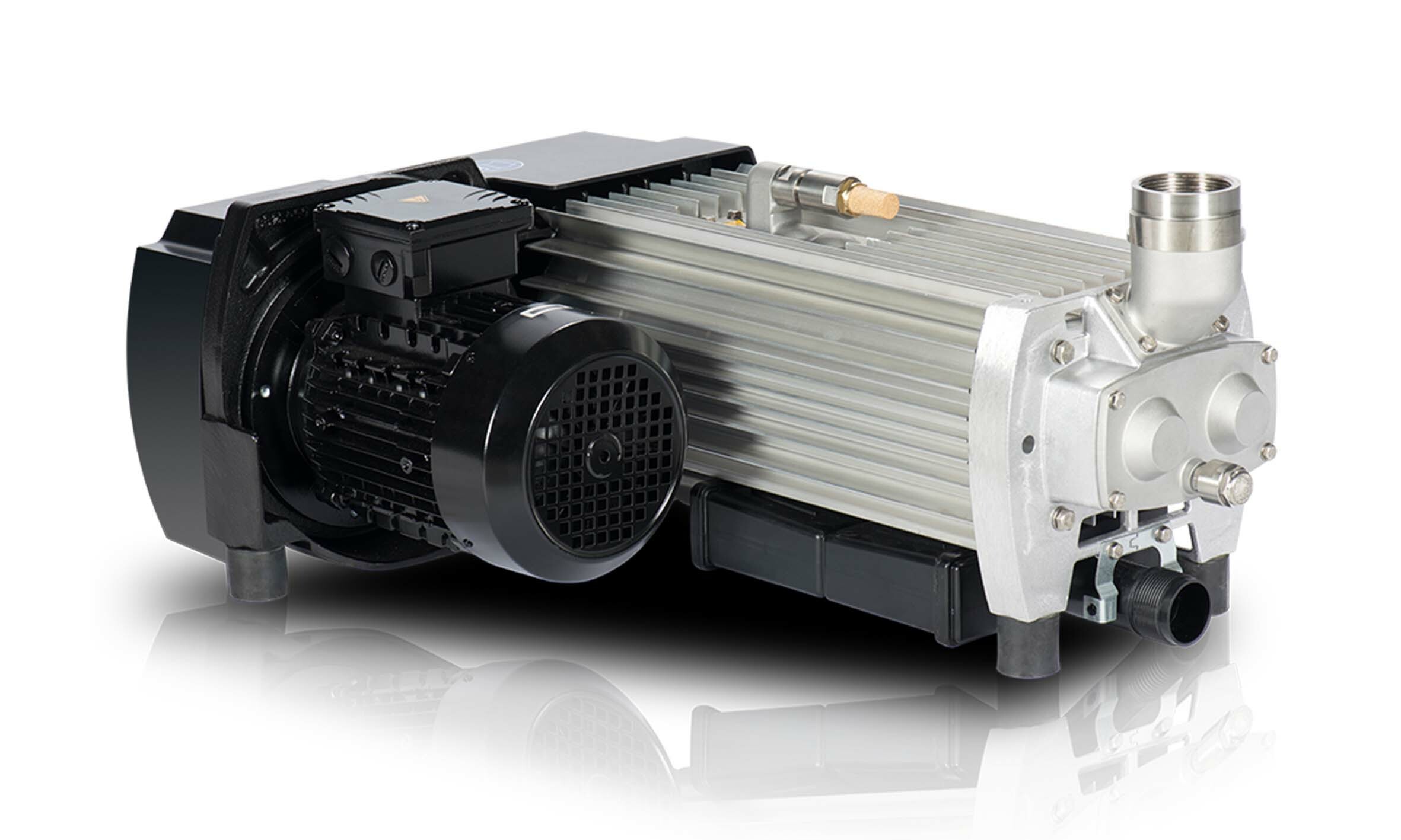

China Good quality Oil Air Cooled Series Screw Vacuum Pump for Electronics Industry and Semiconductor Oil Low Price High Efficient vacuum pump ac

Product Description

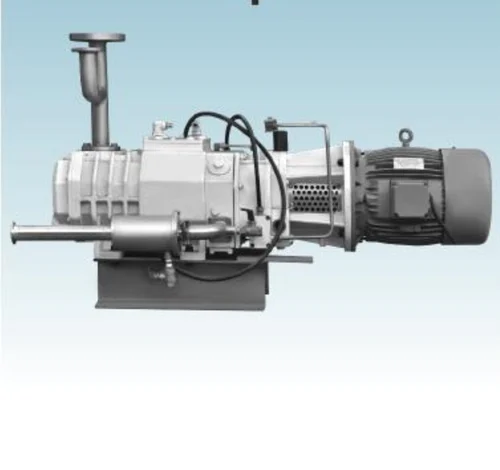

EXTERIOR DESIGN INTERIOR DESIGN

ZheJiang CHINAMFG Machinery Manufacturing Co. , Ltd. is located in HangZhou, ZheJiang .CHINAMFG is a comprehensive screw air compressor

manufacturer that engaged in R & D, design, production and sales. It has a plant of 20,000 square meters, including a large production workshop,

a comprehensive first-class exhibition hall and a testing laboratory.

CHINAMFG has excellent mechanical engineering designers, an experienced staff team and a professional management team. The production

concept focuses on energy-saving and is committed to perfecting and improving the technological process in order to get the core technology

of super frequency energy-saving, achieving the characteristics of mute, durability, power saving and safety.

The company has 9 series of products with multiple models. Including Fixed speed air compressor, PM VSD air compressor, PM VSD

two-stage air compressor, 4-in-1 air compressor, Oil free water lubrcating air compressor, Diesel portable screw air compressor, Electric

portable screw air compressor, Air dryer, Adsorption machine and the matching spare parts. CHINAMFG adheres to the business philosophy of

cooperation and mutual benefit to provide a one-stop service for every customer!

CHINAMFG air compressors not only cover the domestic market but also are exported to more than 20 countries and regions such as South

Africa, Australia, Thailand, Russia, Argentina, Canada and so on. CHINAMFG products have won a good reputation from users for their excellent

quality and style. The company has always adhered to the concept of quality first, service first and dedication to providing every customer with

excellent products and meticulous after-sales service!

CHINAMFG warmly welcome customers to visit our factory and establish a wide range of cooperation!

Frequency Asked Question:

Q1: Are you factory or trade company?

A1: We are factory.

Q2: What the exactly address of your factory?

A2: Our Factory is Located in Xihu (West Lake) Dis. County, HangZhou City, ZheJiang Province, China.

Q3: Will you provide spare parts of your products?

A3: Yes, We provide all parts to customer, so you can do repair or maintenance without trouble.

Q4: Can you accept OEM orders?

A4: Yes, with professional design team, OEM orders are highly welcome.

Q5: How long will you take to arrange production?

A5: Immediate delivery for stock products.380V 50HZ we can delivery the goods within 3-15 days. Other voltage or other color we will delivery within 25-30 days.

Q6: Warranty terms of your machine?

A6: Two years warranty for the machine and technical support always according to your needs.

Q7: Can you provide the best price?

A7:According to your order, we will provide you the best price. /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | 24 Hours |

|---|---|

| Warranty: | 1 Year, 2 Year |

| Lubrication Style: | Lubricated |

| Cooling System: | Air Cooling |

| Power Source: | AC Power |

| Cylinder Position: | Horizontal |

| Customization: |

Available

|

|

|---|

How do screw vacuum pumps compare to other types of vacuum pumps in terms of performance?

Screw vacuum pumps offer several advantages and unique characteristics compared to other types of vacuum pumps. Here’s a detailed explanation of how screw vacuum pumps compare to other vacuum pump types in terms of performance:

1. Efficiency and Energy Consumption:

Screw vacuum pumps are known for their high efficiency and energy-saving capabilities. Compared to other types of vacuum pumps, such as rotary vane pumps or liquid ring pumps, screw vacuum pumps typically have a higher efficiency rating. They achieve this through design features like internal compression, which minimizes energy losses and reduces power consumption. The efficient operation of screw vacuum pumps can result in lower operating costs and reduced environmental impact.

2. Vacuum Level and Flow Rate:

Screw vacuum pumps are capable of achieving both high vacuum levels and high flow rates. They are particularly well-suited for applications requiring a wide operating range, from low to medium vacuum levels. While other types of pumps, like rotary vane pumps, may excel in certain vacuum ranges, screw vacuum pumps offer a versatile performance that suits a variety of industrial applications.

3. Handling of Wet and Contaminated Gases:

Screw vacuum pumps exhibit good tolerance for wet and contaminated gases. They can handle gases containing moisture, condensable vapors, particulates, or even liquid droplets without significant performance degradation. This capability makes screw vacuum pumps suitable for applications where the pumped gases may contain impurities or where condensation is likely to occur. In comparison, some other types of pumps may be more sensitive to moisture or require additional equipment, such as gas traps or separators, to handle wet or contaminated gases effectively.

4. Reliability and Maintenance:

Screw vacuum pumps are generally known for their reliability and low maintenance requirements. They have a robust design with fewer moving parts compared to certain types of pumps, such as rotary vane pumps or liquid ring pumps. This simpler design contributes to reduced wear and tear, resulting in longer service intervals and lower maintenance costs. Additionally, screw vacuum pumps often have longer service life due to their durable construction and efficient operation.

5. Noise and Vibration:

Screw vacuum pumps tend to produce lower noise levels and vibration compared to some other types of pumps. The design of screw vacuum pumps, with balanced rotors and reduced internal clearances, helps minimize noise and vibration during operation. This characteristic can be advantageous in applications where noise reduction and a quieter working environment are desired.

6. Size and Compactness:

Screw vacuum pumps are generally compact in size, making them suitable for installations where space is limited. Their compact design allows for easier integration into existing systems or equipment layouts. In comparison, some other types of pumps, such as liquid ring pumps or some types of dry pumps, may have larger footprints or require additional ancillary equipment, which can pose challenges in space-constrained environments.

7. Specific Application Considerations:

It’s important to note that the choice of vacuum pump type should consider the specific requirements of the application. While screw vacuum pumps offer numerous advantages, certain applications may benefit from the characteristics of other vacuum pump types. For example, oil-sealed rotary vane pumps may be preferred in applications requiring very high vacuum levels, while dry scroll pumps may be suitable for oil-free or cleanroom environments.

In summary, screw vacuum pumps offer high efficiency, versatility in vacuum level and flow rate, good tolerance for wet and contaminated gases, reliability with low maintenance requirements, reduced noise and vibration levels, compactness, and space-saving advantages. However, it is crucial to evaluate the specific needs of the application and consult with experts to determine the most suitable vacuum pump type for optimal performance and efficiency.

Can screw vacuum pumps be used in pharmaceutical and chemical industries?

Yes, screw vacuum pumps can be used in both the pharmaceutical and chemical industries. Here’s a detailed explanation of their applications and benefits in these industries:

Pharmaceutical Industry:

In the pharmaceutical industry, screw vacuum pumps play a crucial role in various processes, including:

1. Drying and Dehydration: Screw vacuum pumps are used for drying pharmaceutical products, such as tablets, powders, and granules. They create a vacuum environment that facilitates the removal of moisture, ensuring product stability and extending shelf life.

2. Distillation and Evaporation: Screw vacuum pumps are employed in distillation and evaporation processes to remove solvents, concentrate solutions, or separate components. They enable precise control over temperature and pressure conditions, ensuring efficient and high-quality separation of pharmaceutical compounds.

3. Filtration and Sterilization: Screw vacuum pumps are utilized in filtration systems to create suction for the filtration of pharmaceutical liquids and solutions. They are also employed in sterilization processes, such as autoclaves, where they help create the necessary vacuum conditions for steam sterilization.

4. Freeze Drying: Screw vacuum pumps are commonly used in freeze drying, also known as lyophilization, which is a widely used method for preserving sensitive pharmaceutical products. They facilitate the removal of water from frozen products under vacuum, preserving their structure, stability, and efficacy.

Chemical Industry:

In the chemical industry, screw vacuum pumps find applications in various processes, including:

1. Vacuum Distillation: Screw vacuum pumps are employed in vacuum distillation processes to separate and purify chemical compounds based on their boiling points. They create a vacuum environment that lowers the boiling points of the substances, enabling more efficient separation and reducing the energy required for the process.

2. Solvent Recovery: Screw vacuum pumps are used for solvent recovery in chemical production. They help remove solvents from mixtures, allowing for their reuse and reducing waste and environmental impact.

3. Vacuum Filtration: Screw vacuum pumps are utilized in vacuum filtration systems to facilitate the separation of solids from liquids or gases. They create suction that aids in the filtration process, improving efficiency and throughput.

4. Reactor Applications: Screw vacuum pumps are employed in various reactor applications, including creating vacuum conditions for chemical reactions that require low pressure or removing byproducts or unreacted gases from the reaction vessel.

Benefits:

There are several benefits of using screw vacuum pumps in the pharmaceutical and chemical industries:

1. Efficiency: Screw vacuum pumps offer high pumping speeds, allowing for rapid evacuation and faster processing times in pharmaceutical and chemical processes.

2. Control: Screw vacuum pumps can be easily integrated into automated systems, allowing for precise control and adjustment of vacuum levels, temperature, and other process parameters.

3. Versatility: Screw vacuum pumps can handle a wide range of chemical compounds and pharmaceutical products, making them suitable for diverse applications in these industries.

4. Reliability: Screw vacuum pumps are known for their robust construction and reliable performance, ensuring continuous operation and minimizing downtime.

5. Oil-Free Operation: Many screw vacuum pumps are designed for oil-free operation, which is essential in pharmaceutical and chemical applications where contamination from lubricating oil must be avoided.

6. Compliance: Screw vacuum pumps can meet the stringent requirements and standards of the pharmaceutical and chemical industries, including Good Manufacturing Practice (GMP) guidelines and safety regulations.

In summary, screw vacuum pumps are well-suited for applications in the pharmaceutical and chemical industries. Their efficiency, control capabilities, versatility, reliability, oil-free operation, and compliance with industry standards make them valuable assets in various processes, ranging from drying and distillation to filtration and sterilization.

What are the different types of screw vacuum pumps available in the market?

There are several different types of screw vacuum pumps available in the market, each with its own design and operating characteristics. Here are some of the commonly used types of screw vacuum pumps:

1. Single-Stage Screw Vacuum Pumps:

Single-stage screw vacuum pumps consist of a single pair of intermeshing screws (rotors) that rotate to create vacuum. These pumps are commonly used for low to medium vacuum applications and can achieve a wide range of vacuum levels. Single-stage screw vacuum pumps are known for their compact design, high pumping speed, and efficient operation.

2. Multi-Stage Screw Vacuum Pumps:

Multi-stage screw vacuum pumps consist of multiple stages, each with its own pair of intermeshing screws. The gas or vapor is sequentially compressed and evacuated through multiple stages, allowing for higher vacuum levels to be achieved. Multi-stage screw vacuum pumps are suitable for applications requiring deeper vacuum levels, such as in chemical processing, power generation, and semiconductor manufacturing.

3. Dry Screw Vacuum Pumps:

Dry screw vacuum pumps operate without the use of any lubricating fluid in the pumping chamber. These pumps rely on tight clearances between the rotors and housing to create a seal and achieve vacuum. Dry screw vacuum pumps are preferred in applications where oil contamination or the presence of lubricating fluids is undesirable, such as in the electronics, pharmaceutical, and food processing industries.

4. Liquid Ring Screw Vacuum Pumps:

Liquid ring screw vacuum pumps combine the principles of liquid ring vacuum pumps and screw vacuum pumps. These pumps use a liquid ring as the sealing and compression medium, while the screws provide the positive displacement action. Liquid ring screw vacuum pumps are known for their capability to handle wet processes and carryover of liquid or condensable vapors. They are commonly used in applications where both liquid and gas handling is required, such as in chemical processing, wastewater treatment, and oil refining.

5. Variable Pitch Screw Vacuum Pumps:

Variable pitch screw vacuum pumps feature rotors with varying helical pitches along their length. This design allows for better optimization of the compression process and improved efficiency. Variable pitch screw vacuum pumps are often used in applications that require a wide operating range and high efficiency, such as in semiconductor manufacturing, research laboratories, and vacuum coating processes.

6. Oil-Injected Screw Vacuum Pumps:

Oil-injected screw vacuum pumps utilize injected oil as a sealing and lubricating medium. The oil creates a seal between the rotors and housing and provides lubrication to minimize friction. These pumps are commonly used in industrial applications where a higher level of vacuum is required, such as in power plants, chemical processes, and central vacuum systems.

7. Oil-Free Screw Vacuum Pumps:

Oil-free screw vacuum pumps are designed to operate without the use of any lubricating oil or fluid. These pumps employ alternative methods, such as dry running or the use of non-contacting technologies, to achieve the necessary sealing and lubrication. Oil-free screw vacuum pumps are favored in applications where oil contamination is a concern, such as in electronics manufacturing, pharmaceutical production, and food processing.

These are just a few examples of the different types of screw vacuum pumps available in the market. The choice of the most suitable type depends on specific application requirements, desired vacuum levels, process conditions, and industry standards.

editor by Dream 2024-05-07

China wholesaler CHINAMFG Small High Performance High Pressure Diaphragm DC Air Pump, Mini Membrane Brush DC Vacuum Pump with Good quality

Product Description

Topsflo Small High Performance High Pressure Diaphragm DC Air Pump, Mini Membrane Brush DC Vacuum Pump

Description:

CHINAMFG micro diaphragm pumps and compressors are based on a simple principal, the circular power from the motor is converted into oscillating movement by an eccentric, which moves up and down its central point, this motion is then transferred to a diaphragm by means of a connecting rod, an elastic diaphragm, which in conjunction with an inlet and outlet valve creates a pumping action.

The TM 40 Series offers multiple component configurations allowing them to be used for either vacuum operation, pressure operation, or alternating vacuum and pressure operations.The innovative, compact design incorporates leading edge technologies that allow it to operate harder, quieter and longer, reliabler, highly efficient.

TM 40 pumps can be mounted in any position and can deliver up to 13 l/min, 16L/min (dual head) depending on the model and will operate against pressures of up to 280Kpa.

Specification:

| Model |

Pressure Pump | Vacuum Pump | Rated Voltage | No-load Current | Max Pressure | Max Vacuum | Max Flow |

| (Item Number) | (Item Number) | (Vdc) | (A) | (KPa) | (KPa) | (L/min) | |

| TM40-B | TM40A-B01-12-P22013 | TM40A-B01-12-V8013 | 12 | 0.7 | 220 | -80 | 13 |

| TM40-B02-12-P28016 | TM40A-B02-12-V8016 | 12 | 1.2 | 280 | -80 | 16 | |

| ” P ” means pressure pump, ” V ” means vacuum pump, “12/24” means different voltages optional. | |||||||

| Pump Weight:280g; Pump Size:86*mm*65mm*40.5mm; Inlet&Outlet:OD 6.5mm/ID 3.4mm,hose suggestion:ID 5.0mm | |||||||

| Materials:pump head Nylon, membrane EPDM, valve EPDM Motor type and code:”B”means economical brush DC motor (reference lifetime ≥1,000hours) |

|||||||

Features:

Highest Performance/Size Ratio

Innovative and efficient engineering designs enable the TM 40 Series to push the performance envelope in a lightweight, compact size.

Performs Quieter

Optimized head, chamber, and flow path reduce noise without compromising performance.

Lasts Reliably Longer

Uncontaminated flow

no contamination of the media due to oil-free operation

Little vibration

Because of leading edge technologies, top quality bearing, superior brushless motor

High level of gas tightness

thanks to stress-optimised structured diaphragm, newly-designed valves and sealing systems, precise placement of the pump head

Extreme chemical resistance

The use of chemically resistant materials optional such as PTFE FKM or other ,material combinations for the parts which allows the corrosive gas to be pumped.

Optimal solution for your application

a wide standard range of materials, motors , voltages configurates multiple components system selected

Typical Application:

Industrial pressure and vacuum applications

Portable Analytical Instruments

Medical Diagnostic Equipment

Air Quality Sampling Monitors

Respiration Monitors

Gas or Odor Leak Detectors

Dimension(mm) & Curve:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Material: | Head Nylon, Membrane EPDM / PTFE, Valve EPDM / FPM |

|---|---|

| Power: | Electric |

| Function: | Electronic Type |

| Motor: | DC Brush,Motor |

| Materials: | Pump Head Nylon, Membrane EPDM / PTFE, Valve EPDM |

| Life-Time: | 1200hour |

| Customization: |

Available

|

|

|---|

Can Vacuum Pumps Be Used for Vacuum Packaging?

Yes, vacuum pumps can be used for vacuum packaging. Here’s a detailed explanation:

Vacuum packaging is a method used to remove air from a package or container, creating a vacuum environment. This process helps to extend the shelf life of perishable products, prevent spoilage, and maintain product freshness. Vacuum pumps play a crucial role in achieving the desired vacuum level for effective packaging.

When it comes to vacuum packaging, there are primarily two types of vacuum pumps commonly used:

1. Single-Stage Vacuum Pumps: Single-stage vacuum pumps are commonly used for vacuum packaging applications. These pumps use a single rotating vane or piston to create a vacuum. They can achieve moderate vacuum levels suitable for most packaging requirements. Single-stage pumps are relatively simple in design, compact, and cost-effective.

2. Rotary Vane Vacuum Pumps: Rotary vane vacuum pumps are another popular choice for vacuum packaging. These pumps utilize multiple vanes mounted on a rotor to create a vacuum. They offer higher vacuum levels compared to single-stage pumps, making them suitable for applications that require deeper levels of vacuum. Rotary vane pumps are known for their reliability, consistent performance, and durability.

When using vacuum pumps for vacuum packaging, the following steps are typically involved:

1. Preparation: Ensure that the packaging material, such as vacuum bags or containers, is suitable for vacuum packaging and can withstand the vacuum pressure without leakage. Place the product to be packaged inside the appropriate packaging material.

2. Sealing: Properly seal the packaging material, either by heat sealing or using specialized vacuum sealing equipment. This ensures an airtight enclosure for the product.

3. Vacuum Pump Operation: Connect the vacuum pump to the packaging equipment or directly to the packaging material. Start the vacuum pump to initiate the vacuuming process. The pump will remove the air from the packaging, creating a vacuum environment.

4. Vacuum Level Control: Monitor the vacuum level during the packaging process using pressure gauges or vacuum sensors. Depending on the specific packaging requirements, adjust the vacuum level accordingly. The goal is to achieve the desired vacuum level suitable for the product being packaged.

5. Sealing and Closure: Once the desired vacuum level is reached, seal the packaging material completely to maintain the vacuum environment. This can be done by heat sealing the packaging material or using specialized sealing mechanisms designed for vacuum packaging.

6. Product Labeling and Storage: After sealing, label the packaged product as necessary and store it appropriately, considering factors such as temperature, humidity, and light exposure, to maximize product shelf life.

It’s important to note that the specific vacuum level required for vacuum packaging may vary depending on the product being packaged. Some products may require a partial vacuum, while others may require a more stringent vacuum level. The choice of vacuum pump and the control mechanisms employed will depend on the specific vacuum packaging requirements.

Vacuum pumps are widely used in various industries for vacuum packaging applications, including food and beverage, pharmaceuticals, electronics, and more. They provide an efficient and reliable means of creating a vacuum environment, helping to preserve product quality and extend shelf life.

Considerations for Selecting a Vacuum Pump for Cleanroom Applications

When it comes to selecting a vacuum pump for cleanroom applications, several considerations should be taken into account. Here’s a detailed explanation:

Cleanrooms are controlled environments used in industries such as semiconductor manufacturing, pharmaceuticals, biotechnology, and microelectronics. These environments require strict adherence to cleanliness and particle control standards to prevent contamination of sensitive processes or products. Selecting the right vacuum pump for cleanroom applications is crucial to maintain the required level of cleanliness and minimize the introduction of contaminants. Here are some key considerations:

1. Cleanliness: The cleanliness of the vacuum pump is of utmost importance in cleanroom applications. The pump should be designed and constructed to minimize the generation and release of particles, oil vapors, or other contaminants into the cleanroom environment. Oil-free or dry vacuum pumps are commonly preferred in cleanroom applications as they eliminate the risk of oil contamination. Additionally, pumps with smooth surfaces and minimal crevices are easier to clean and maintain, reducing the potential for particle buildup.

2. Outgassing: Outgassing refers to the release of gases or vapors from the surfaces of materials, including the vacuum pump itself. In cleanroom applications, it is crucial to select a vacuum pump with low outgassing characteristics to prevent the introduction of contaminants into the environment. Vacuum pumps specifically designed for cleanroom use often undergo special treatments or use materials with low outgassing properties to minimize this effect.

3. Particle Generation: Vacuum pumps can generate particles due to the friction and wear of moving parts, such as rotors or vanes. These particles can become a source of contamination in cleanrooms. When selecting a vacuum pump for cleanroom applications, it is essential to consider the pump’s particle generation level and choose pumps that have been designed and tested to minimize particle emissions. Pumps with features like self-lubricating materials or advanced sealing mechanisms can help reduce particle generation.

4. Filtration and Exhaust Systems: The filtration and exhaust systems associated with the vacuum pump are critical for maintaining cleanroom standards. The vacuum pump should be equipped with efficient filters that can capture and remove any particles or contaminants generated during operation. High-quality filters, such as HEPA (High-Efficiency Particulate Air) filters, can effectively trap even the smallest particles. The exhaust system should be properly designed to ensure that filtered air is released outside the cleanroom or passes through additional filtration before being reintroduced into the environment.

5. Noise and Vibrations: Noise and vibrations generated by vacuum pumps can have an impact on cleanroom operations. Excessive noise can affect the working environment and compromise communication, while vibrations can potentially disrupt sensitive processes or equipment. It is advisable to choose vacuum pumps specifically designed for quiet operation and that incorporate measures to minimize vibrations. Pumps with noise-dampening features and vibration isolation systems can help maintain a quiet and stable cleanroom environment.

6. Compliance with Standards: Cleanroom applications often have specific industry standards or regulations that must be followed. When selecting a vacuum pump, it is important to ensure that it complies with relevant cleanroom standards and requirements. Considerations may include ISO cleanliness standards, cleanroom classification levels, and industry-specific guidelines for particle count, outgassing levels, or allowable noise levels. Manufacturers that provide documentation and certifications related to cleanroom suitability can help demonstrate compliance.

7. Maintenance and Serviceability: Proper maintenance and regular servicing of vacuum pumps are essential for their reliable and efficient operation. When choosing a vacuum pump for cleanroom applications, consider factors such as ease of maintenance, availability of spare parts, and access to service and support from the manufacturer. Pumps with user-friendly maintenance features, clear service instructions, and a responsive customer support network can help minimize downtime and ensure continued cleanroom performance.

In summary, selecting a vacuum pump for cleanroom applications requires careful consideration of factors such as cleanliness, outgassing characteristics, particle generation, filtration and exhaust systems, noise and vibrations, compliance with standards, and maintenance requirements. By choosing vacuum pumps designed specifically for cleanroom use and considering these key factors, cleanroom operators can maintain the required level of cleanliness and minimize the risk of contamination in their critical processes and products.

How Do You Choose the Right Size Vacuum Pump for a Specific Application?

Choosing the right size vacuum pump for a specific application involves considering several factors to ensure optimal performance and efficiency. Here’s a detailed explanation:

1. Required Vacuum Level: The first consideration is the desired vacuum level for your application. Different applications have varying vacuum level requirements, ranging from low vacuum to high vacuum or even ultra-high vacuum. Determine the specific vacuum level needed, such as microns of mercury (mmHg) or pascals (Pa), and choose a vacuum pump capable of achieving and maintaining that level.

2. Pumping Speed: The pumping speed, also known as the displacement or flow rate, is the volume of gas a vacuum pump can remove from a system per unit of time. It is typically expressed in liters per second (L/s) or cubic feet per minute (CFM). Consider the required pumping speed for your application, which depends on factors such as the volume of the system, the gas load, and the desired evacuation time.

3. Gas Load and Composition: The type and composition of the gas or vapor being pumped play a significant role in selecting the right vacuum pump. Different pumps have varying capabilities and compatibilities with specific gases. Some pumps may be suitable for pumping only non-reactive gases, while others can handle corrosive gases or vapors. Consider the gas load and its potential impact on the pump’s performance and materials of construction.

4. Backing Pump Requirements: In some applications, a vacuum pump may require a backing pump to reach and maintain the desired vacuum level. A backing pump provides a rough vacuum, which is then further processed by the primary vacuum pump. Consider whether your application requires a backing pump and ensure compatibility and proper sizing between the primary pump and the backing pump.

5. System Leakage: Evaluate the potential leakage in your system. If your system has significant leakage, you may need a vacuum pump with a higher pumping speed to compensate for the continuous influx of gas. Additionally, consider the impact of leakage on the required vacuum level and the pump’s ability to maintain it.

6. Power Requirements and Operating Cost: Consider the power requirements of the vacuum pump and ensure that your facility can provide the necessary electrical supply. Additionally, assess the operating cost, including energy consumption and maintenance requirements, to choose a pump that aligns with your budget and operational considerations.

7. Size and Space Constraints: Take into account the physical size of the vacuum pump and whether it can fit within the available space in your facility. Consider factors such as pump dimensions, weight, and the need for any additional accessories or support equipment.

8. Manufacturer’s Recommendations and Expert Advice: Consult the manufacturer’s specifications, guidelines, and recommendations for selecting the right pump for your specific application. Additionally, seek expert advice from vacuum pump specialists or engineers who can provide insights based on their experience and knowledge.

By considering these factors and evaluating the specific requirements of your application, you can select the right size vacuum pump that meets the desired vacuum level, pumping speed, gas compatibility, and other essential criteria. Choosing the appropriate vacuum pump ensures efficient operation, optimal performance, and longevity for your application.

editor by Dream 2024-05-03

China manufacturer DN300 Large Roots Blower Vacuum Pump 6000m3/H Air Cooling Type vacuum pump electric

Product Description

COMPANY PROFILE

B-Tohin Machine (ZheJiang ) Co., Ltd., a foreign-funded enterprise, was established in 1994 with a registered capital of 120 million yuan. located in HangZhou Environmental Science and Technology Industrial Park, China. It is mainly engaged in the production and sales of Roots blowers, rotary blowers, single-stage high-speed centrifugal blowers, multi-stage centrifugal blowers, air bearing turbo blower, maglev turbo blower, screw blowers, fiberglass blowers, stainless steel blowers, MVR blowers, vacuum pumps, water pumps and other products, as well as the distribution of ShinMaywa pumps imported from Japan. The products are used in environmental protection water treatment, building materials cement, chemical industry, electric power, petroleum, steel, metallurgy, mining, printing and dyeing, grain transportation, new energy and new materials and other industries, the products are sold all over the country, and exported to many countries and regions. At present, there are more than 310 employees, the annual sales value of 450 million yuan, the production of various types of blowers about 30,000 sets.

Passed the certification of ISO9001 & ISO 14001:2400, the company also has been certified as “High & New-tech Enterprises of ZheJiang Province”, “Pneumatic Technology Research Center of ZheJiang Province”, “Well-known Trademark of China”, “Famous Trademark of ZheJiang Province”and “Eco-friendly Products”, and it has achieved many patents of state level and National CHINAMFG Plan Projects.In successive 7 years, B-Tohin has been honored as “Favorite Brand of Users in Water Treatment Industry” and “Leading Enterprise in Chinese Roots Blower Industry, and in 2014, it has been ranked “2014 Top 10 Brands in Chinese Water Industry”.

BLG permanent magnet variable frequency screw blower:

1.The male and female rotors of the oil-free screw blower are precisely designed. Compared with roots blower, they achieve internal compression in the cavity, and are more efficient and save more than 20% energy under the same energy consumption conditions.

2.The conveying air volume is stable, and the air volume fluctuates less with the change of pressure.

3.It has higher conveying pressure and lower operating noise.

4.It can be controlled by PLC intelligent remote control, using a variety of communication methods, and convenient operation and management.

2. Product features

Design concept:

(1) Main structure: dry oil-free twin-screw rotor design, using spiral internal compression mode, no pulse of air output. Ductile iron production, high efficiency, rotor surface coating, strong adhesion, extend the life of the main engine.

Bearings: CHINAMFG original composite bearings adapt to changing loads, providing a high degree of flexibility and efficiency.

Seal: Labyrinth seal, carbon ring seal combination or gas seal, magnetic oil seal combination, to provide oil-free and dust-free pure compression chamber.

(2) More efficient and energy saving: The high efficiency and energy saving screw blower adopts oil-free screw energy-saving host and permanent magnet frequency conversion system, which has more intuitive economic benefits than the traditional Roots fan. Oil-free screw blower based on the principle of thermal compression, the total efficiency of more than 75%, than Roots fan energy saving about 10%. It also has higher exhaust pressure and lower pressure pulse.

(3) More stable and reliable: After high temperature performance test, durable and reliable, multi-duct air intake, can overcome a variety of complex conditions.

(4) Lower noise: The pneumatic noise of the screw fan is very small, the smooth output eliminates the sudden release of the internal air, and the air rattle of the wavy inlet and outlet is reduced, making the fan noise less than the traditional blower, without whistling. Due to the internal compression of the helical rotor, the pressure impact noise of the blower outlet pressure and pipeline pressure is eliminated, the gas is output smoothly, and the wave inlet and air outlet reduce the airflow fluctuation. Box screw overall noise ≤85 dB.

(5) Stability

Compared with Roots blowers:

The unit has small leakage, low temperature rise and strong pressure boost, up to 150KPa (1.5bar).

Compared with centrifugal blowers:

Strong adaptability to working conditions, no surge, flow rate almost does not change with pressure changes.

(6) Intelligence

The integrated skid box can be installed and moved as a whole. Site installation workload is less, only need to complete the interface pipe